Transmission maintenance is a crucial aspect of vehicle care that often goes overlooked. Many drivers focus on engine health while neglecting the complex system responsible for transferring power to the wheels. Regular upkeep of transmission components can prevent costly repairs, extend vehicle lifespan, and ensure optimal performance. By understanding the critical parts and implementing a proactive maintenance strategy, you can avoid major transmission issues and keep your vehicle running smoothly for years to come.

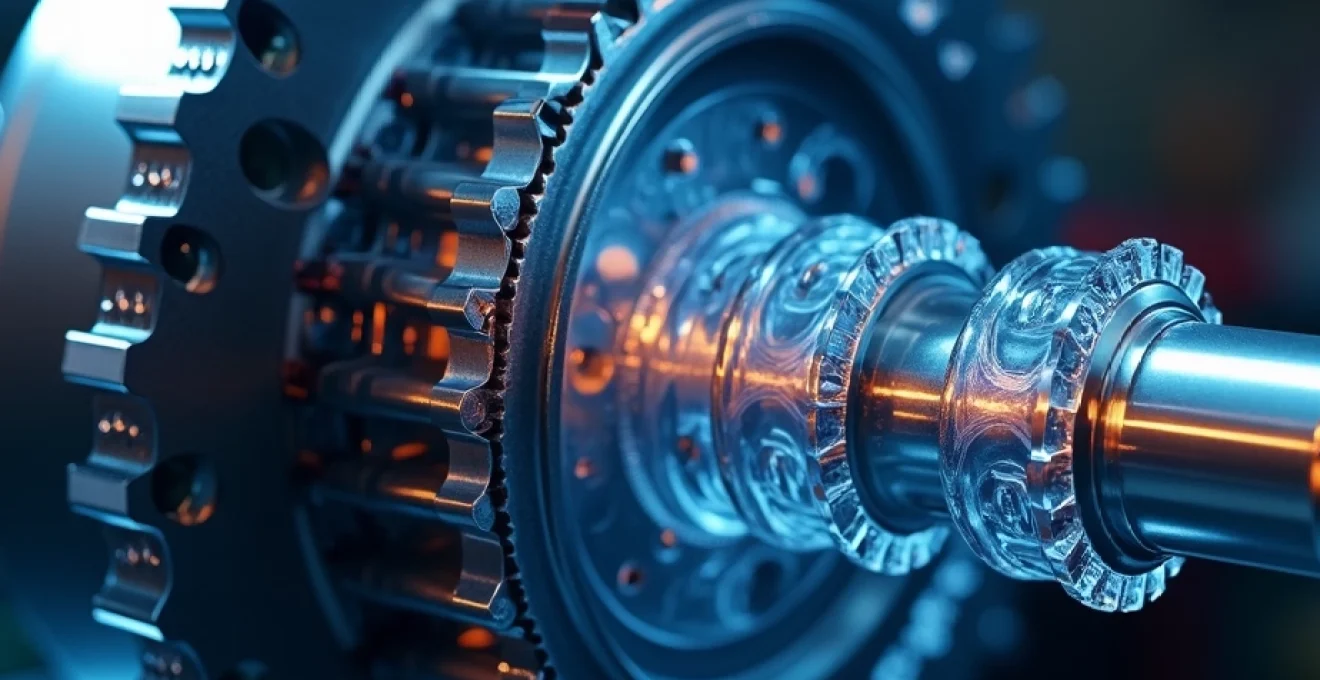

Transmission components: identifying critical parts for maintenance

The transmission system comprises numerous intricate parts, each playing a vital role in the vehicle's operation. Identifying these components is the first step in developing an effective maintenance routine. Key elements include the torque converter, clutch packs, planetary gear sets, and the electronic control module (ECM). Regular inspection and maintenance of these parts can prevent wear and tear, ensuring smooth gear transitions and optimal power transfer.

One often overlooked component is the transmission cooler. This vital part helps regulate the temperature of the transmission fluid, preventing overheating and subsequent damage. Ensuring the cooler is clean and functioning properly can significantly extend the life of your transmission. Additionally, the transmission mounts, which secure the transmission to the vehicle's frame, require periodic checks to prevent excessive movement and potential misalignment.

Fluid analysis: key indicator of transmission health

Transmission fluid is the lifeblood of your vehicle's gearbox. Regular analysis of this fluid can provide invaluable insights into the overall health of your transmission system. By examining the fluid's condition, you can detect early signs of wear, contamination, or degradation, allowing for timely interventions that can prevent major failures.

Viscosity testing: detecting wear and contamination

Viscosity testing is a critical component of fluid analysis. This process measures the fluid's resistance to flow, which can indicate the presence of contaminants or the breakdown of the fluid itself. Changes in viscosity can affect the transmission's ability to shift gears smoothly and protect internal components from wear. Regular viscosity testing can help you identify when it's time to change the fluid or address potential issues before they escalate.

Metal content analysis: pinpointing internal damage

The presence of metal particles in transmission fluid is a telltale sign of internal wear. Through metal content analysis, you can identify which specific components may be deteriorating. For example, high levels of copper might indicate wear on bushings or thrust washers, while elevated iron content could point to issues with gears or clutch plates. This precision in diagnostics allows for targeted repairs, potentially saving you from more extensive and expensive overhauls.

Oxidation measurement: assessing fluid degradation

Oxidation occurs when transmission fluid breaks down due to heat and exposure to air. This process can lead to the formation of sludge and varnish, which can clog passages and interfere with the smooth operation of the transmission. Measuring oxidation levels helps determine the fluid's remaining useful life and can guide decisions on when to perform a fluid change. Proactive fluid replacement based on oxidation levels can prevent the accumulation of harmful deposits within the transmission.

TAN (Total Acid Number): evaluating fluid acidity levels

The Total Acid Number (TAN) is a measure of the acidity present in the transmission fluid. As fluid degrades, its acidity increases, which can lead to corrosion of metal components and deterioration of seals. Monitoring the TAN allows you to track the fluid's degradation over time and schedule replacements before the acidity reaches levels that could damage the transmission. Regular TAN testing is an essential part of a comprehensive fluid analysis program.

Torque converter maintenance: preventing slippage and overheating

The torque converter is a critical component in automatic transmissions, responsible for transferring power from the engine to the transmission. Proper maintenance of the torque converter can prevent issues such as slippage, which occurs when the converter fails to efficiently transfer power, leading to decreased performance and increased fuel consumption. Regular inspections can identify early signs of wear or damage to the converter's internal components, such as the stator, impeller, and turbine.

Overheating is another common problem that can be prevented through proper torque converter maintenance. Excessive heat can cause the fluid inside the converter to break down, leading to reduced efficiency and potential damage to seals and other components. Ensuring proper fluid levels and regularly flushing the transmission system can help maintain optimal operating temperatures and prevent heat-related issues.

Clutch pack inspection: ensuring smooth gear transitions

Clutch packs are integral to the smooth operation of both manual and automatic transmissions. These components are responsible for engaging and disengaging gears, allowing for seamless transitions between different speed ratios. Regular inspection of clutch packs can identify wear patterns, contamination, or damage that could lead to slipping, harsh engagement, or complete failure of the transmission.

Friction material wear patterns: diagnosing engagement issues

The friction material on clutch plates is designed to wear gradually over time. However, abnormal wear patterns can indicate underlying problems with the transmission. Uneven wear might suggest misalignment or warped plates, while excessive wear could point to contaminated fluid or improper pressure. By inspecting these wear patterns, technicians can diagnose engagement issues early and recommend appropriate repairs or adjustments.

Steel plate warpage: identifying thermal stress damage

Steel plates in the clutch pack can warp due to excessive heat, causing inconsistent clutch engagement and potential transmission failure. Regular inspection for signs of warpage, such as discoloration or visible distortion, can help identify thermal stress damage before it leads to more serious issues. Addressing warped plates promptly can prevent further damage to the transmission and ensure smooth operation.

Spline wear assessment: detecting misalignment problems

The splines on clutch plates and hubs are critical for proper engagement and power transfer. Wear on these splines can lead to slipping, noise, and eventual transmission failure. Regular assessment of spline wear can detect misalignment problems or excessive wear, allowing for timely replacement of affected components. This proactive approach can prevent more extensive damage and costly repairs down the line.

Planetary gear set care: maximizing power transfer efficiency

Planetary gear sets are at the heart of many automatic transmissions, responsible for providing different gear ratios and enabling smooth power transfer. Proper care of these complex components is essential for maintaining transmission efficiency and longevity. Regular inspection of the sun gear, planet gears, and ring gear can identify wear, pitting, or damage that could lead to transmission failure if left unchecked.

Lubrication is critical for planetary gear sets. Ensuring that these components receive adequate, clean fluid can significantly reduce wear and extend their lifespan. Additionally, checking for proper clearances and backlash between gears can help maintain optimal performance and prevent premature wear. By incorporating planetary gear set care into your regular maintenance routine, you can maximize power transfer efficiency and avoid costly repairs.

Electronic control module (ECM) diagnostics: optimizing shift quality

Modern transmissions rely heavily on electronic control modules to manage gear shifts, fluid pressure, and overall performance. Regular diagnostics of the ECM can identify software issues, sensor malfunctions, or wiring problems that could affect shift quality and transmission efficiency. Keeping the ECM updated with the latest software can also improve shift patterns and overall transmission performance.

Solenoid testing: verifying precise pressure control

Transmission solenoids play a crucial role in controlling fluid pressure and flow within the transmission. Regular testing of these components can ensure they are functioning correctly, providing precise pressure control for smooth gear changes. Faulty solenoids can lead to harsh shifts, slipping, or even complete transmission failure. By incorporating solenoid testing into your maintenance routine, you can catch and address issues before they escalate into more serious problems.

Sensor calibration: ensuring accurate speed and position data

Accurate sensor data is essential for proper transmission operation. Speed sensors, position sensors, and temperature sensors all provide critical information to the ECM. Regular calibration and testing of these sensors ensure that the transmission receives accurate data, allowing for optimal shift timing and quality. Addressing sensor issues promptly can prevent erratic shifting and potential damage to transmission components.

Software updates: implementing latest shift algorithms

Manufacturers often release software updates to improve transmission performance and address known issues. Keeping your transmission's software up to date can lead to smoother shifts, better fuel efficiency, and improved overall performance. Regular checks for available updates and implementing them as part of your maintenance routine can help your transmission operate at its best.

Adaptive learning reset: fine-tuning transmission performance

Many modern transmissions use adaptive learning to adjust shift patterns based on driving habits and conditions. Periodically resetting this adaptive learning can allow the transmission to relearn and optimize its performance. This process can be particularly beneficial after major repairs or when addressing shift quality issues. Incorporating adaptive learning resets into your maintenance schedule can help maintain optimal transmission performance over time.